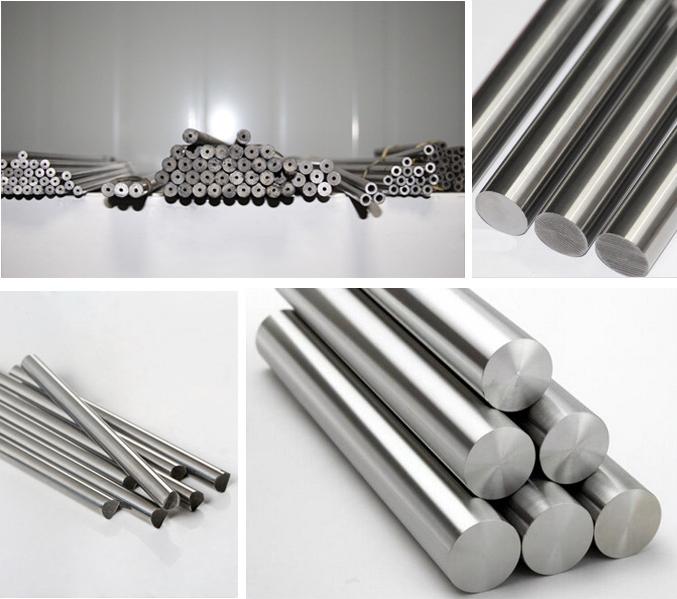

Rodungiyoyin Tongten Carbide shine carbide zagaye zagaye na kunnuwa, wanda aka sani da magungunan ungsten karfe, mai sauƙin faɗi mashaya ko tungsten zagaye mashaya. Carbide Carbide abu ne mai amfani da kayan aikin da aka samar kuma ya ƙunshi mahaɗan ƙarfe na gyarawa (wuya) da kuma haɗin ƙarfe (lokaci mai ban sha'awa).

Akwai hanyoyi guda biyu don samar da sandunan kundin katako na Togsten: ɗayan yana da ƙarfi, da ɓoyewa shine hanyar da ta dace don samar da kyawawan sanduna. Ana iya tayar da shi zuwa kowane lokaci wanda mai amfani da mai amfani ya fi wanda yake amfani da shi a lokacin tsari. Koyaya, tsawon gaba ɗaya ba zai iya wuce 350mm ba. Sauran shine matsi da matsawa, wanda shine hanyar da ta dace don samar da gajerun hannun jari. Kamar yadda sunan ya nuna, ana matse shi carbide foda ana guga foda cikin siffar tare da mold.

Cemented Carbide yana da jerin kyawawan abubuwan da ke motsa jiki kamar babban ƙarfi, ƙarfin hali da kuma tauri, da har yanzu yana da babban ƙarfi a 1000 ° C. Aadden Tungso aka yi amfani da shi azaman kayan kayan aiki, kamar kayan masarufi, kayan ƙarfe, dutse, da sauran manganese sayan ruwa (ƙwayoyin ƙwaya, Bayyan ajiya, Z-Mier, Granulator ---), latsa (tare da matsi da hydraulic latsa ko extreting kore, haɗa wuta ko kuma high flower matsa lamba).

Kayan kayan abinci suna jingina da mayafi, bushewa, manne da lalacewa, kuma a ƙarshe samar da fafatawa na ƙarshe da fikantarwa da hira.

Rashin amfani da keɓaɓɓun mashaya mai wucewa shine cewa tsarin samarwa yana da tsawo. Nasin kananan diamita zagaye sanders a ƙasa 3mm da watse thearshen ƙarshen biyu zai ɓata takamaiman adadin kayan. Da ya fi tsawon tsawon carbide ƙananan ƙananan diamita zagaye sandar mashaya, mafi muni daidai na blank. Tabbas, kai tsaye da matsalolin zagaye na zagaye za'a iya inganta su ta hanyar silidanric nika a wani mataki na gaba.

Wani kuma shine matsawa da matsawa, wanda shine hanyar gajeriyar jari an samar. Kamar yadda sunan ya nuna, masarufi ne wanda ke fuskantar foda Carbide cikin tsari. Amfanin wannan hanyar Carbide san hanya shine cewa za a iya kafa ta a cikin guda pass da rage scrap. Sauƙaƙe tsarin yankan waya kuma suna kawar da yanayin bushewa na hanyar wucewa. Lokaci na sama na gajere na iya ajiye abokan ciniki 7-10 kwana.

Tsananin magana, m matsatsin kuma na matsawa da matsawa. Matsakaicin matsakaiciyar hanya ce mai kyau don samar da manyan sandunansu mai tsayi da katako mai tsawo. Ta hanyar manyan piston da ƙananan piston, cakuda cunkoso ya shigar da matsakaici na ruwa da kuma roba mai matsawa, kuma ana amfani da matsi ta roba mai narkewa don yin gurnani carbide.

Lokaci: Jan-24-2024