Tsarin Tungsten Carbide an yi shi ne da alama ta Carbide da Coppert foda, da CO A cikin amfani da tsinkayen tungsten, da kuma matsakaiciyar WC da kuma mahimmancin WC da co, abin da aka gyara na WC da co, abubuwan da aka gyara WC da kuma mahimmancin WC da co, abin da aka gyara na WC da kuma co, abubuwan da aka gyara WC da kuma mahimmin abu, mai latsa da kuma suna na carbide ba, kuma kewayon suna da yawa.

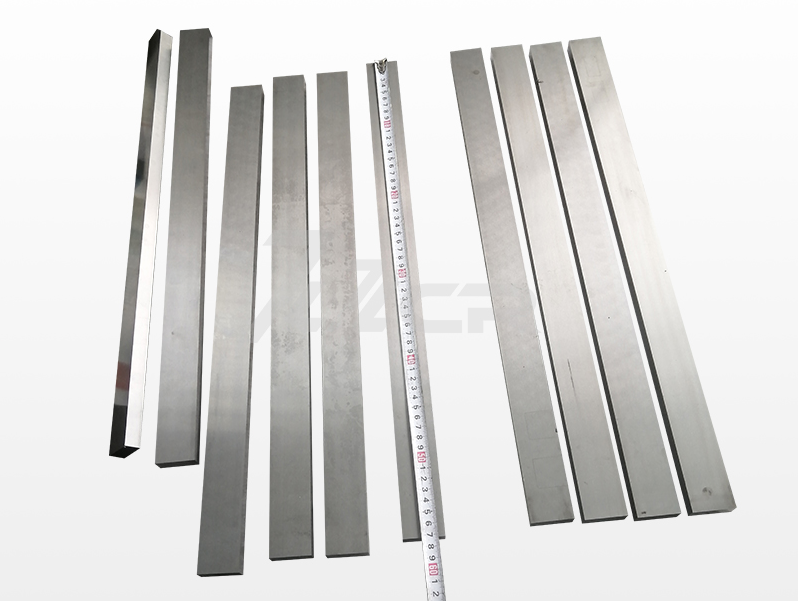

Daya daga cikin abubuwanda suka fi na Tubegten Carbips, an mai suna saboda fasalin faranti (ko murabba'ai), wanda kuma aka sani da Togneten Carbide StrIP / faranti. Tsarin Tungsten Carbide yana da taka kyau sosai, kyakkyawan sanyawa na resisting, acid da lantarki da lantarki a cikin baƙin ƙarfe da allurarta.

Menene dalilan danazarinna tungsten carbips? Chuangrui Carbide zai amsa na gaba:

(1) Buring a cikin Tongten Carbide ba takalmin ko goge shi kafin walwani, da kuma sahun kaya a kan murin rigar da ƙarfe kuma ya raunana ƙarfin weld.

(2)NazarinZai kuma faruwa lokacin da aka zaɓi wakilin da aka yi amfani da shi da kyau, alal misali, lokacin da ake amfani da Borax a matsayin wakilin Brazing sosai a kan farjin ƙasa, da kumanazarinsabon abu yana faruwa.

(3) daidai zazzabi zai zama 30 ~ 50 ° C sama da melting m karfe na m karfe, kumanazarinZai faru idan yawan zafin jiki ya yi yawa ko ya yi ƙasa. Haumla da yawa na iya haifar da iskar shaka a cikin Weld. Yin amfani da karfe-dauke da ƙarfe mai dauke da karfi zai ba da weel mai launin shuɗi ko fari. Lokacin da zazzabi mai ƙarfin gwiwa ya yi ƙasa sosai, za a kafa Weld mai lokacin farin ciki, kuma a ciki na Weld za a rufe shi da porolos da slag m. Yanayin da ke sama zasu rage ƙarfin Weld, kuma yana da sauƙin deweld lokacin da aka yi amfani ko amfani.

(4) A cikin tsarin rera, babu slag lokacin sakin lokaci ko kuma isasshen sakin slag, saboda haka yakai yawan wakilin Brazing da haddasanazarin.

Lokaci: Aug-28-2024