Tongsten Carbide Peferical

Siffantarwa

An yi amfani da carbide carbide spherical anyi amfani da shi sosai a cikin dusar kankara don hakar mai da kuma cire dusar ƙanƙara. Bugu da kari, ana iya cutar da carbide na carbide da kayan kwalliya na carbide a cikin yankan kayan aikin da injin hakar ma'adanai, kiyayewa. Ana amfani da haƙoran ƙwallon ƙafa na carbide da aka yi amfani da shi a yawancin kayan aikin da ke gudana, hadi, tunatar da gine-gine.

Roƙo

Ana amfani da maɓallin Carbide da aka sani sosai a cikin faifan filayen mai da kuma cire dusar ƙanƙara, dusar ƙanƙara ko wasu kayan aikinsu na musamman. Dangane da injunan masu fashin ban mamaki, kamar suzuzuwan, kayan aikin dtholy, kayan aikin carbide. Daddare da babban fasaha suna tabbatar da ingancin samfuranmu, ana yawan amfani da kayan haɗin gwiwar carbide a matsayin kayan aikin hearer da kayan aikin gyaran hanya. Hakanan ana amfani da carbide carbide ball hakora suma ana amfani dashi azaman kayan aikin rami da ke kwance, hutun hakar tunwasawa da ginin farar fata. Bugu da kari, an kuma amfani dashi azaman dacewa sosai ga rawar jiki mai nauyi ko kuma mai zurfi na kayan aiki mai zurfi.

Fasas

Cemented Carbide shine mafi kyawun kayan don samar da tabbacin carbide na carbide na carbide wanda aka yi amfani da shi sosai a masana'antar dill hammer.

Ana amfani da maɓallin Carbide sosai a cikin ma'adinai, ana kwance da yankan saboda ƙarfinsu. Hakanan za'a iya amfani dasu a cikin bits mai nauyi.

Daraja

| Daraja | Yawag / cm3 | TRS MA MPA | ƘanƙanciHRA | Roƙo |

| Cr4c | 15,10 | 1800 | 90.0 | Galibi ana amfani da su don yankan kayan masarufi da taushi. |

| CR6 | 14.95 | 1900 | 90.5 | Amfani da shi azaman kwalba na lantarki, petrooleum cone ragowa da scraper ball-hakori. |

| Kru | 14.80 | 2200 | 89.5 | Amfani da shi a matsayin babban dills, kwalba na lantarki, petrooleum mazugi da ballos da scraper ball haƙoran hakori. |

| Cr8C | 14.80 | 2400 | 88.5 | Galibi ana amfani da shi azaman ball haƙoran matsakaici da ƙananan tasiri bit kuma kamar yadda ke ɗauke da daji na Rushewar Binciken Bincike. |

| CR11C | 14.40 | 2700 | 86.5 | Yawancin ana amfani da su a cikin tasirin tasowa kuma a cikin conne dills don yanke ƙwallon haƙoran kayan masarufi na manyan kayan aiki. |

| CR13C | 14.2 | 2850 | 86.5 | Da yawa amfani da yankan ƙwallon ƙafa na matsakaici da kayan aiki masu ƙarfi a cikin tasirin motsi. |

| CR15C | 14.0 | 3000 | 85.5 | Amfani da shi ga mazugi mai matsakaici-taushi da matsakaici-mai matsakaici-wuya-wuya mai kayan aiki. |

Gimra

An karba Oem.

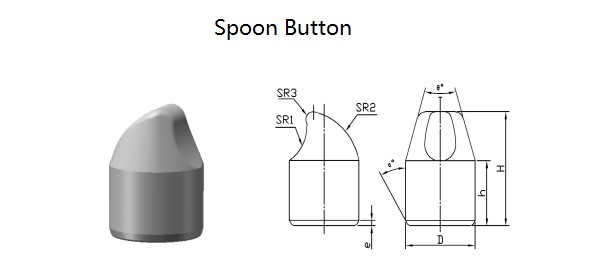

Matsakaicin girman maɓallin Togneten Kamarulan:

| Iri | Girma (mm) | ||||||||

| D | H | h | ° | SR1 | SR2 | SR3 | ° ° | e | |

| S1015 | 10.25 | 15 | 9.8 | 50 | 12 | 20 | 3 | 18 | 1.2 |

| S1116 | 11.3 | 16.5 | 10.2 | 50 | 15 | 24 | 3 | 18 | 1.2 |

| S1218 | 12.35 | 18 | 11 | 36 | 20 | 25 | 2.5 | 18 | 1.5 |

| S1319 | 13.35 | 19 | 12 | 50 | 15 | 20 | 3 | 18 | 1.5 |

| S1421 | 14.35 | 21 | 12.5 | 40 | 12 | 25 | 3 | 18 | 1.8 |

| S1521 | 15.35 | 21 | 12 | 50 | 20 | 30 | 3 | 18 | 1.8 |

| S1624 | 16.35 | 24 | 13 | 30 | 15 | 20 | 3 | 18 | 2 |

| S1827 | 18.25 | 27 | 14.5 | 30 | 18 | 20 | 3 | 18 | 2 |

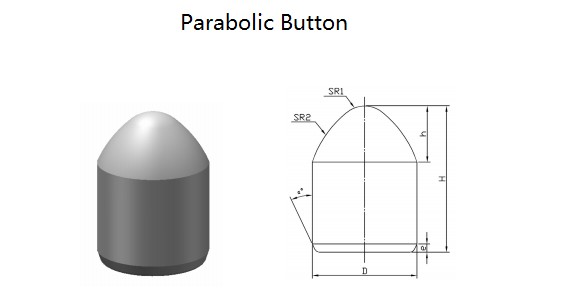

| Iri | Girma (mm) | |||||||

| D | H | SR1 | SR2 | h | ° ° | β ° | e | |

| D0711 | 7.25 | 11 | 1.9 | 8.7 | 3.9 | 20 | 25 | 1.6 |

| D0812 | 8.25 | 12 | 2.5 | 9 | 4.5 | 20 | 25 | 1.6 |

| D0913 | 9.25 | 13 | 2.5 | 11 | 5 | 20 | 25 | 1.8 |

| D1015 | 10.25 | 15 | 3.2 | 11.8 | 5 | 20 | 25 | 1.8 |

| D1117 | 11.3 | 17 | 3 | 13.5 | 6 | 20 | 25 | 1.8 |

| D1218 | 12.35 | 18 | 3 | 12 | 6.5 | 20 | 20 | 2 |

| D1319 | 13.35 | 19 | 3.5 | 13.5 | 7.1 | 20 | 20 | 2 |

| D1420 | 14.35 | 20 | 4.2 | 13 | 8 | 20 | 20 | 2 |

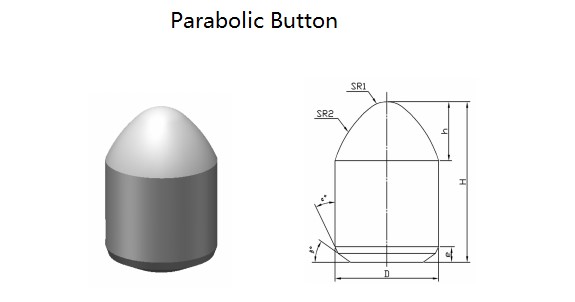

| Iri | Girma (mm) | ||||||

| D | H | SR1 | SR2 | h | ° ° | e | |

| D0711A | 7.25 | 11.0 | 1.9 | 8.7 | 3.9 | 18 | 1 |

| D0812A | 8.25 | 12.0 | 2.5 | 9 | 4.5 | 18 | 1 |

| D0913A | 9.25 | 13.0 | 2.5 | 11 | 5 | 18 | 1 |

| D1015A | 10.25 | 15.0 | 3.2 | 11.8 | 5 | 18 | 1.2 |

| D1117A | 11.3 | 17.0 | 3 | 13.5 | 6 | 18 | 1.2 |

| D1218A | 12.35 | 18.0 | 3 | 12 | 6.5 | 18 | 1.5 |

| D1319A | 13.35 | 19.0 | 3.5 | 13.5 | 7.1 | 18 | 1.5 |

| D1420A | 14.35 | 20.0 | 4.2 | 13 | 8 | 18 | 8 |

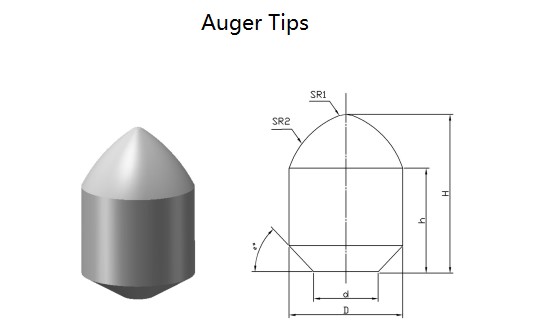

| Iri | Girma (mm) | |||||

| D | d | H | h | SR1 | SR2 | |

| Jm1222 | 12 | 3.0 | 22 | 15 | 1.5 | 26 |

| JM1425 | 14 | 4.0 | 25 | 17 | 1.5 | 26 |

| JM1625 | 16 | 5.0 | 25 | 16 | 1.5 | 26 |

| JM1828 | 18 | 5.0 | 28 | 18 | 1.5 | 26 |

| JM2428 | 24 | 10.1 | 28 | 16 | 2 | 36 |

| JM2534 | 25 | 18.0 | 34 | 20 | - | 25 |

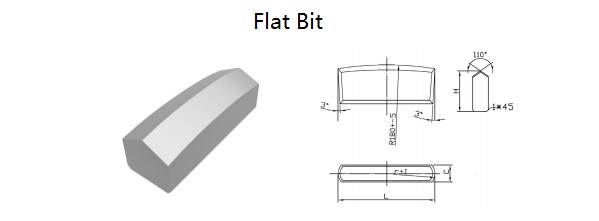

| Iri | Girma (mm) | |||||

| L | H | C | r | |||

| A | B | C | ||||

| K026 | 26 | 18.0 | 15 | 12.5 | 8 | 13 |

| K028 | 28 | 18.0 | 15 | 12.5 | 8 | 14 |

| K030 | 30 | 18.0 | 15 | 12.5 | 8 | 15 |

| K032 | 32 | 18.0 | 15 | 12.5 | 8 | 16 |

| K034 | 34 | 18.0 | 15 | 12.5 | 8 | 17 |

| K036 | 36 | 18.0 | 15 | 12.5 | 10 | 18 |

| K038 | 38 | 18.0 | 15 | 12.5 | 10 | 19 |

| K040 | 40 | 18.0 | 15 | 12.5 | 10 | 20 |

| K042 | 42 | 18.0 | 15 | 12.5 | 10 | 21 |

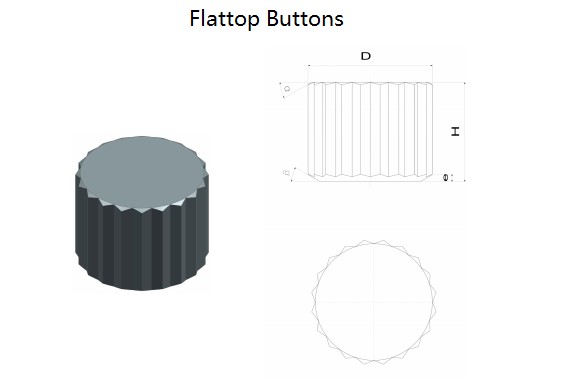

| Iri | Girma (mm) | ||||

| D | H | t | ° ° | e | |

| MH0806 | 8 | 6.0 | 0.5 | 25 | 1.1 |

| MH1008 | 10 | 8.0 | 0.5 | 25 | 1.9 |

| MH1206 | 12 | 6.0 | 0.5 | 25 | 1.9 |

| MH1208 | 12 | 8.0 | 0.5 | 25 | 2.5 |

| MH1410 | 14 | 10.0 | 0.5 | 25 | 2.5 |

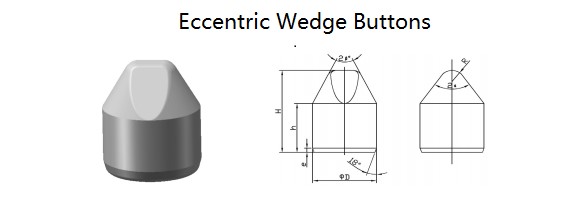

| Iri | Girma (mm) | |||||||

| D | H | h | R | r | ° ° | β ° | e | |

| X0810 | 8 | 10 | 6.5 | 2 | 1.8 | 45 | 22.5 | 1.5 |

| X1011 | 10 | 11 | 7 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1013 | 10 | 13 | 9 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1115 | 11 | 15 | 8 | 2.8 | 2.5 | 22.5 | 22.5 | 1.5 |

| X1215 | 12 | 15 | 9 | 3 | 2.5 | 45 | 22.5 | 1.5 |

| X1217 | 12 | 17 | 10.5 | 3.5 | 3 | 35 | 20 | 1.5 |

| X1418 | 14 | 18 | 10 | 3.5 | 3 | 45 | 22.5 | 1.5 |

| X1420 | 14 | 20 | 11 | 2.7 | 3 | 35 | 22.5 | 1.5 |

| X1520 | 15 | 20 | 12 | 3 | 3 | 40 | 22.5 | 1.5 |

| X1621 | 16 | 21 | 11 | 2.6 | 3 | 35 | 22.5 | 2 |

| X1623 | 16 | 23 | 12 | 3 | 3.5 | 30 | 18 | 2 |

| X1721 | 17 | 21 | 13 | 4 | 3.5 | 40 | 22.5 | 2 |

| X1724 | 17 | 24 | 13 | 3.5 | 3.5 | 30 | 22.5 | 2 |

| X1929 | 19 | 29 | 17 | 4 | 3 | 30 | 15 | 2 |

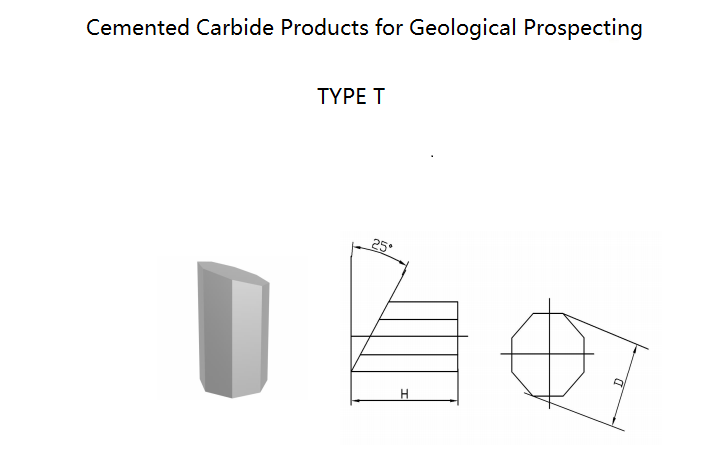

| Iri | Girma (mm) | |

| D | H | |

| T105 | 5 | 10 |

| T106 | 7 | 10 |

| T107 | 7 | 15 |

| T109 | 9 | 12 |

| T110 | 10 | 16 |

Amfaninmu

Maɓallin Carbide da ke da alama yana da mafi girman juriya da tasiri mai tsauri, kuma yana da saurin yin amfani da kayayyaki masu kama da samfuran iri ɗaya. Rayuwar da ba ta cinye ta kasance kusan sau 5-6 ba muddin dai na bit ɗin tare da diamita na aiki, yana rage aiki tuƙuru da saurin saurin injiniya.

Don ƙarin bayani, barka da karba mu a kowane lokaci!

Kayan aiki

Rigar Grinding

Fesa bushewa

Tura

TPA latsa

Semi-latsa

Hip Siffar

Sarrafa kayan aiki

Hakowa

Yankan waya

A tsaye nika

Universal Grinding

Jirgin sama niƙa

CNC Milling inji

Kayan dubawa

Hardness mita

Dabara

Matsayi na Quadratic kashi

Cobalt Magnetic kayan aiki

Metallographic micrcope